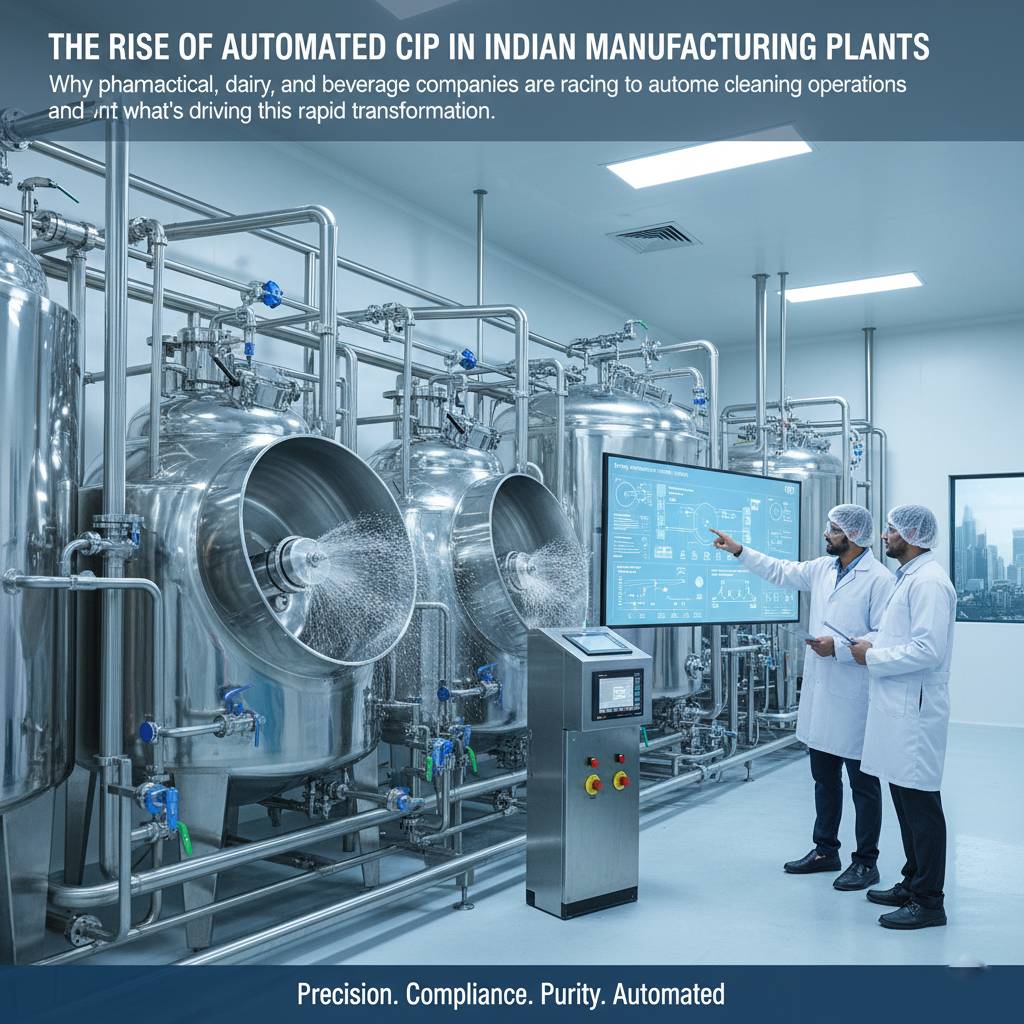

The Rise of Automated CIP in Indian Manufacturing Plants

It's a fundamental shift happening at remarkable speed across Indian manufacturing, driven by compliance demands, rising costs, and a new generation of cleaning technology that actually works

.jpg)

By Charles Pandian

Why pharmaceutical, dairy, and beverage companies are racing to automate their cleaning operations and what's driving this rapid transformation.

Walk into any modern pharmaceutical plant in Ahmedabad, Hyderabad, or Bangalore today, and you'll notice something different. The days of operators manually hosing down tanks and relying on intuition to determine when a vessel is "clean enough" are rapidly disappearing.

In their place: automated Clean-In-Place (CIP) systems, precision-engineered spray balls, and data-logged cleaning cycles that can prove not just promise contamination-free production.

This isn't a gradual evolution. It's a fundamental shift happening at remarkable speed across Indian manufacturing, driven by compliance demands, rising costs, and a new generation of cleaning technology that actually works.

Why Compliance Is Forcing Plants to Automate

USFDA inspections have become increasingly stringent. Export audits now demand granular documentation. Even domestic regulators are tightening requirements for batch-to-batch consistency. Plants that once relied on "experience-based" cleaning protocols are scrambling to implement systems that can prove repeatability.

Automated CIP delivers exactly what auditors want to see: repeatable cleaning cycles with zero operator variability, logged parameters for every wash and rinse step, consistent coverage at validated flow rates and pressures, and faster batch changeovers without compromising cleanliness.

The shift is profound. Automation has evolved from an efficiency tool into a compliance necessity. For export-focused pharma companies, it's becoming the difference between passing inspections and losing market access.

The Hidden Cost Crisis: Water and Energy

Here's a number catching boardroom attention: 18–32% increase in utility costs over just two years.

Water isn't cheap anymore, especially in water-stressed regions where pharmaceutical and food plants operate. Poorly calibrated manual CIP systems waste thousands of liters per cycle, use excessive chemicals to compensate for poor coverage, require extended heating times, and need multiple rinse cycles because operators can't verify cleanliness.

Automated systems, paired with high-efficiency rotating spray balls, deliver 20 to 40% reductions in water consumption, 15–25% lower chemical usage, reduced heating loads through optimized cycle times, and shorter rinse periods with better first-pass cleaning.

Many companies have set aggressive targets: reduce CIP utility consumption by 20 to 40% before FY26. For them, automation isn't just smart, it's financially imperative.

The Workforce Reality Nobody Talks About

Here's an uncomfortable truth plant managers quietly acknowledge: young operators don't want to do high-touch CIP jobs anymore.

Manual tank cleaning is physically demanding, repetitive, and frankly, unappealing to the new generation of workers. High turnover in cleaning crews creates consistent nightmares, every new operator brings different habits, different attention to detail, and different results.

Automated CIP eliminates operator dependency on critical cleaning steps, reduces human error during sanitation protocols, provides repeatable cycle logic regardless of who's on shift, enables remote monitoring from control rooms, and frees skilled manpower for higher-value troubleshooting and optimization.

In high-stakes pharma environments where batch failures can cost millions, this reliability isn't a luxury; it's essential.

The Technology Breakthrough: Smarter Cleaning Hardware

The biggest misconception about CIP automation? It requires ripping out entire systems and starting from scratch.

The reality is more accessible. Much of the transformation is happening at the component level, particularly inside tanks. Modern spray technology has evolved dramatically.

Today's pharma-grade rotating spray balls deliver optimized droplet impact for faster cleaning, controlled flow rates that reduce water load without sacrificing performance, and better coverage in complex tank geometries. SS316L electropolished surfaces meet GMP compliance standards, while Hastelloy options handle aggressive chemical environments. Complete IQ/OQ/PQ documentation packages, material certificates, and predictable spray pattern mapping support validation protocols. Seamless compatibility with automated CIP skids and inline sensors enables real-time monitoring.

A single modern rotating spray ball today accomplishes what an entire manual cleaning team couldn't achieve consistently a decade ago.

Who's Leading the Adoption Wave

Dairy Plants require frequent cleaning to maintain strict microbial standards. Plants that switched from manual rinsing to automated CIP report 20 to 30% reductions in cleaning downtime, allowing them to process more batches daily without compromising safety.

Breweries depend on absolute cleanliness for product consistency. Yeast residues, protein deposits, and hop oils must be removed uniformly, batch after batch. Automated CIP delivers measurable improvements in product consistency and significantly fewer off-spec batches linked to contamination.

Pharmaceuticals face the highest stakes, and adoption is accelerating fastest here. Automated CIP aligns perfectly with Annex 1 sterile manufacturing requirements, cross-contamination control between API batches, complete traceability for every cleaning cycle, batch reconciliation with zero ambiguity, and cleaning validation with defensible data.

With Indian pharmaceutical exports booming and regulatory scrutiny intensifying, CIP automation is rapidly moving from "recommended" to non-negotiable.

The Numbers That Changed the Conversation

When engineering teams quantify CIP improvements, the business case becomes undeniable:

| Benefit | Typical Impact |

| Faster changeovers | +1–2 additional batches per week |

| Water consumption | 20–40% savings |

| CIP chemical usage | 15–25% reduction |

| Manpower dependency | Dramatically higher reliability |

| Audit readiness | Zero stress during inspections |

| Component lifespan | Lower maintenance, fewer replacements |

Most plants recover their CIP automation investment within 18–24 months. After that? Pure operational advantage.

What Plants Are Demanding Now

Today's plant heads want specific capabilities. On the hardware side: validated SS316L or Hastelloy spray balls with documented material traceability, electropolished finishes meeting 0.4–0.8 Ra specifications, rotating spray ball options for removing difficult residues, retractable spray heads for reactor cleaning, and predictable, mappable spray patterns for validation.

For documentation and compliance: complete IQ, OQ, PQ protocols, material certificates, validation support from suppliers, and cleaning efficacy data.

Performance metrics matter: measurable reductions in water consumption per cycle, compatibility with automated CIP skids, and inline monitoring capability for flow, pressure, and turbidity.

The era of "good enough" components is over. Plants want automation-ready hardware backed by documentation.

Three Trends Defining the Future

The shift from static spray balls to rotating spray systems is accelerating due to measurable performance gains in cleaning difficult residues and complex geometries. Flow meters, pressure sensors, and turbidity monitors are becoming standard across CIP skids—enabling real-time verification rather than post-cleaning sampling. Cloud reporting, cleaning cycle analytics, and predictive maintenance schedules mean CIP is becoming part of the digital plant ecosystem, not a standalone operation.

The era of "approximate cleaning" is ending. Precision is the new standard.

Why This Matters Now

India's manufacturing sector is experiencing explosive growth. Pharmaceutical exports alone are projected to reach $130 billion by 2030. Dairy production is scaling rapidly. Craft breweries are proliferating.

But growth brings scrutiny from regulators, customers, and international partners.

Plants that modernize their CIP systems now will unlock faster production cycles through reduced changeover times, lower operating costs via utility optimization, cleaner audits with defensible documentation, competitive advantage in export markets, and operational reliability that compounds over years.

The Bottom Line

The rise of automated CIP in India isn't just a technological trend, it's the new backbone of efficient, high-compliance manufacturing.

The question isn't whether to automate. It's how quickly you can implement systems that will define operational excellence for the next decade. The plants making this investment today aren't just keeping up they're building an unassailable competitive advantage.

Ready to Transform Your CIP Operations?

Jetspray Innovations Pvt Ltd specializes in pharmaceutical-grade automated CIP systems designed specifically for Indian manufacturing environments. From rotating spray ball technology to complete validation support, we deliver cleaning solutions that eliminate variability, reduce costs, and ensure audit-ready compliance.

Transform your cleaning operations from a compliance challenge into a competitive advantage.

Call our Sales Team: +91 91370 91368

Visit: www.jetspray.in

Jetspray Innovations Pvt Ltd — Engineering precision into pharmaceutical hygiene, one validated cleaning cycle at a time.

Share on

Tags: cip