The Ultimate Guide to Bio-Pharmaceutical Sanitary Valves

A sanitary valve is a precision-engineered flow control device used in industries where strict hygiene and contamination control are critical, such as the biopharmaceutical, food, and beverage sectors.

By Charles Pandian

Leonardo, not DiCaprio, but a star in the biopharma industry, faced a serious issue of cross-contamination across several batches of the product. The valves were used across multiple processes, like fermentation and bioreactor systems, media and buffer preparation, filtration and separation, sterile filling lines, CIP/SIP circuits and much more.

When these valves were replaced with the Jetspray’s sampling equipment, the problem was solved. In this blog, we highlight the significance of these sanitary valves to maintain the product’s integrity, purity, and compliance.

What is a Sanitary Valve?

A sanitary valve is a valve that is specially designed for applications where hygiene standards need to be maintained strictly. This valve helps maintain a sterile environment while regulating the flow of liquids and gases; therefore, it is highly significant in biopharmaceutical industries.

Unlike the other industrial valves, they are made from corrosion-resistant materials like 316 Stainless steel, offering smooth and crevice-free surfaces for easy cleaning and sterilization processes.

Types of Sanitary Valves

A Sanitary Valve can be built with numerous variations. However, we classify sanitary valves based on their mechanical motions here:

1. Linear Motion Valve:

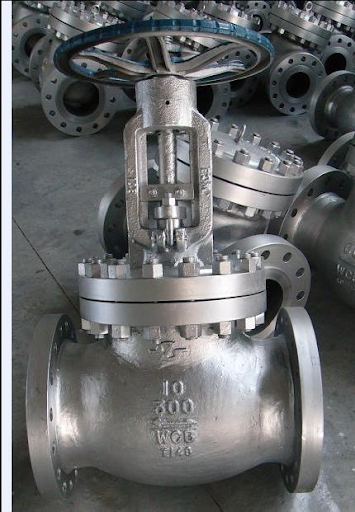

A Linear Motion Valve uses a closing chamber. As it moves in a straight line, it allows, stops, or chokes the medium’s flow. The valve’s stem moves upwards or downwards in a straight motion to open or close it.

Some of the examples of linear motion valves include gate valves, diaphragm valves, and globe valves.

The gate valve is ideal for on/off control and maintains pressure during sampling with a minimum drop. The globe valves are suitable for throttling and flow regulation. But since the diaphragm valves are compatible with CIP systems, they are the most commonly used types of linear motion valves in biopharmaceutical industries.

2. Rotary Motion Valve:

A Rotary Motion Valve has a ball or a disc as a closure element that rotates around the central axis to open or close the flow path.

The Butterfly Valves, Ball Valves, and Plug Valves are the most widely used rotary motion valves in the biopharmaceutical industry.

- A Butterfly Valve is lightweight and compact, and has a rotating disc that controls the flow.

- A Ball Valve has a spherical ball with a bore, allowing the valve to be closed tightly.

- A plug valve has a cylindrical or tapered plug with a hole through which the medium flows.

3. Quarter-Turn Valves:

As per the name, it only turns a quarter of a full circle to move from fully open to fully closed. These valves are a kind of Rotary Motion valve, with the actuator or the

handle rotating the valve element to 90 degrees to open or close the flow path.

Since they have fewer moving parts, it is easy to maintain them.

Key Features of Sanitary Valves in Biopharmaceutical Applications

Here are the critical features present in a sanitary valve:

- CIP/SIP compatibility: It is designed for easy integration with CIP/SIP systems.

- Intert Materials: These valves are made from 316L Stainless steel and have electropolished surfaces.

- Zero-Dead Leg Zones: This avoids product retention in the valve, preventing cross-contamination.

- Compliance with the regulatory standards: Since these valves are designed according to the standards' demands, there is absolutely no risk of violations.

- Easy Disassembling: They can be easily disassembled for cleaning and inspection.

- Smooth Bore Design: It allows unrestricted laminar flow with minimum turbulence.

Standards and Certifications

They must adhere to the following standards and certifications for acceptance in the global markets:

- 3-A Sanitary Standards: It sets the benchmarks for designing and fabricating the equipment suitable to maintain sterile environments.

- FDA Compliance: The Materials used for designing the equipment that comes in contact with the product must comply with the FDA standards.

- ASME BioProcessing Equipment (BPE): It sets the standards for the equipment designs to maintain hygiene.

- USP Class VI: It ensures biocompatibility of the materials used in the valve seals, such as the plastics and elastomers.

What are the Challenges in selecting and maintaining sanitary valves?

Though they are ideal for applications in the biopharmaceutical industry, here are the significant challenges to overcome:

- High cost: The cost of installing an advanced valve can be expensive.

- Downtime delays: Maintaining and servicing them regularly is essential to prevent equipment failure and cross-contamination.

- Documentation and Traceability: For a smooth validation process, it is necessary to ensure every component is fully documented and strictly follows good manufacturing practices.

To choose the right kind of valve, invest in the best sampling solutions.

Jetspray’s Sampling Solutions

Reliable, Simple and Efficient and the three best adjectives that describe the product. Choose our sampling equipment for accurate sampling without compromising the system pressure of the vacuum. Its user-friendly design allows easy cleaning and maintenance on a regular basis.

These sampling solutions are more than just the mechanical components; they are the gatekeepers of the product’s integrity!

Jetspray meets the demand for high-performance, hygienic, and smart valve systems. For more information, visit our website today!

Share on

Tags: nozzles